- How to Install AAC Conductor

- Power cable current carrying capacity

- Guide on Low Voltage Aerial Bundling Cables(ABC Cab

- Guide to Electrical Insulators

- The difference between 3 + 2 and 4 + 1 on wires and

- What are the cable accessories?

- AWG (American Wire Gauge) to MM2 Conversion

- Cable Short Circuit Current Calculate

- Overhead conductor,poles,and gold fittings design

- OPGW Cable Line Design Several Key Issues[2]

E-Mail:info@dosensecable.com

Phone:+8613073786551

Tel:+8613073786551

Add:Zhengzhou, Henan,China

OPGW Cable Line Design Several Key Issues[2]

3 Several key questions

3.1 Disk and reserved length

Because each time the optical fiber signal passes through a connector, a certain attenuation is generated. In actual engineering design, OPGW is generally produced in fixed length, and the connection cannot be connected in the middle. The connector must use a special connection box. Therefore, the segmentation of OPGW should be comprehensively considered in combination with the path conditions of the main line, the construction site, the tower type, and the manufacturing and transportation conditions.

When designing, the number, type and length of optical cable distribution plates should be indicated in the OPGW construction schedule. The length of each reel of optical cable needs to consider the influence of cable sag, as well as the reserved length of splice box and pit stop. Generally, the pole position with connection box is considered to be increased by 60m, and when entering the substation, the reserved length is considered to be 150m.

During the maintenance process of OPGW, it is necessary to extend the optical cable when reconnecting and partially moving. Therefore, appropriate reserved lengths should be made in the design length of OPGW at the joints, complex areas and important spans.

3.2 Mechanical calculation

According to the meteorological conditions of the actual project, the OPGW optical cable must meet the requirements of electrical and mechanical use conditions: ① the design safety factor of the OPGW is greater than the safety factor of the wire; The requirements of S≥0.012L+1 in the regulations; ③Due to the above conditions, the sag of the other ground wire should be kept at the same level as possible. Based on the above requirements, the calculation of the OPGW optical cable characteristic curve and installation curve [2, 3].

3.3 Initial elongation treatment

After the OPGW optical cable is subjected to tensile force, it will produce plastic elongation, which will cause the sag in the gear to increase, so that the safe distance between the OPGW optical cable and the conductor will be reduced, so compensation must be considered in the construction process.

The influence of plastic elongation of OPGW optical cable on sag can be referred to the data provided in Article 7.0.6 of "Technical Specifications for Design of 110-500kV Overhead Transmission Lines", and the cooling compensation treatment shall be carried out according to the requirements of the manufacturer.

3.4 Anti-vibration

Breeze vibration is an eddy current flow phenomenon that often occurs in overhead conductors, ground wires and overhead optical cables. The mechanical principle of breeze vibration occurs when a stable layered wind passes through a cylindrical object such as a fiber optic cable. When the wind blows the cylindrical object, the layered and interlaced vortices behind it form a certain pressure difference, so that the cylindrical object tends to move in the direction perpendicular to the direction of the wind blowing. If the frequency of the eddy current is consistent with the natural frequency of the fiber optic cable, the wire will experience breeze vibration. This kind of breeze vibration is a fatigue hazard to the optical cable.

Commonly used OPGW isolators include anti-vibration hammer, anti-vibration whip, damping line anti-vibration ball and anti-vibration ring. Judging from the existing data, the vibration isolators used for optical cables at home and abroad are mainly anti-vibration hammers and anti-vibration whips. The anti-vibration hammer is a frequency-adjustable vibration damper. It has a very effective anti-vibration effect for large-diameter cables. Its principle is to absorb energy dynamically. The anti-vibration whip is a commonly used impact shock absorber. The anti-vibration whip is very effective in damping the high-frequency vibration of small-diameter cable lines. The anti-vibration whip dissipates the vibration energy through the impact with the cable, and then achieves the effect of reducing the breeze vibration of the line. At present, on OPGW optical cables, both anti-vibration hammers and anti-vibration whips are used.

3.5 Hardware and accessories

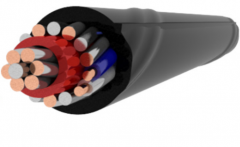

OPGW's main supporting hardware includes suspension clamps, tension clamps, special grounding wires, anti-vibration hammers, down-conductor clamps, hoops, splice boxes, thermoplastic sleeves, etc., which are generally provided by optical cable manufacturers or suppliers. In order to ensure the reliable hanging of the OPGW optical cable on the tower, the corresponding hardware assembly string is generally designed according to the actual situation of the hanging hole of the tower.

3.6 Grounding

The grounding of OPGW is a small but very important part, and many designers tend to miss this issue. The OPGW is reliably grounded on each base tower through a dedicated ground wire. The hardware string is connected to the special grounding wire through the parallel groove clip, and the other end of the grounding wire is bolted to the reserved hole of the tower grounding frame. Generally, one grounding wire is configured for the suspension fitting string, and two grounding wires are configured for the straight-through type and the need to be disconnected.

4 Conclusion

Through the above elaboration of OPGW line design, designers can generally grasp the key issues of OPGW line design, establish a concept of OPGW line design process, start with type selection, and complete the design of the entire project step by step. Since more problems related to OPGW, such as the research on the reasons for lightning strikes and disconnection, are still in the exploratory stage, they still need to be further explored and solved in the future.

Welcome to inquiry to Dosense Cable ! Any question for OPGW design, production, supply and installation, please contact us ! Our email address info@dosensecable.com

- Previous:OPGW cable line design several key issues[1]

- Next:SeaMeWe-6 Submarine Cable System Starts Construction

-

2023-10-02How to Install AAC Conductor

-

2023-08-30Power cable current carrying capacity

-

2022-03-17What are the cable accessories?

-

2022-07-01AWG (American Wire Gauge) to MM2 Conversion

-

2022-05-10OPGW Cable Line Design Several Key Issues[2]

info@dosensecable.com

info@dosensecable.com

Tel:

Tel:  Address: Zhengzhou, Henan,China

Address: Zhengzhou, Henan,China