- How to Install AAC Conductor

- Power cable current carrying capacity

- Guide on Low Voltage Aerial Bundling Cables(ABC Cab

- Guide to Electrical Insulators

- The difference between 3 + 2 and 4 + 1 on wires and

- What are the cable accessories?

- AWG (American Wire Gauge) to MM2 Conversion

- Cable Short Circuit Current Calculate

- Overhead conductor,poles,and gold fittings design

- OPGW Cable Line Design Several Key Issues[2]

E-Mail:info@dosensecable.com

Phone:+8613073786551

Tel:+8613073786551

Add:Zhengzhou, Henan,China

How to Install AAC Conductor

How to Install AAC Conductor-All Aluminium Conductor

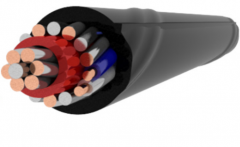

The installation of AAC (Aluminum Conductor) involves several steps to ensure proper electrical conductivity and safety. AAC conductors are commonly used for overhead power transmission and distribution lines due to their lightweight and corrosion resistance. Here are the general steps for the installation of AAC conductors:

1. Preparation and Safety Measures:

- Ensure you have the necessary safety equipment, including helmets, gloves, safety glasses, and insulated tools.

- Verify that the installation team is trained in electrical safety procedures.

- Identify the route for the conductor installation, and check for any obstacles or obstructions.

- Remove any trees, branches, or other obstructions that may interfere with the conductor's installation path.

3. Stringing Equipment:

- Use specialized stringing equipment like tensioners, pullers, and sheaves to handle the conductor safely.

- Ensure that all equipment is in good working condition and properly maintained.

4. Support Structures:

- Install the necessary support structures like poles, towers, or crossarms along the installation path. These should be designed to withstand the mechanical loads and environmental conditions.

5. Tensioning the Conductor:

- The conductor must be tensioned properly to prevent sagging. Tensioning equipment is used to apply the correct tension.

- Pay attention to the manufacturer's recommendations for the specific AAC conductor type being installed.

6. Stringing the Conductor:

- Attach the AAC conductor to the pulling equipment and carefully guide it along the support structures.

- Ensure that the conductor is not damaged during the installation process.

7. Clamping and Termination:

- Use appropriate clamps, connectors, and hardware to secure the conductor to the support structures and any termination points, such as transformers or switches.

8. Clearance and Spacing:

- Maintain the required clearance between conductors and between conductors and ground or other structures, as specified by local regulations and safety standards.

9. Inspection and Testing:

- After installation, conduct a visual inspection to check for any visible defects or issues.

- Perform electrical tests, such as insulation resistance and continuity testing, to ensure the conductor's integrity and electrical performance.

10. Documentation:

- Maintain accurate records of the installation, including conductor specifications, installation dates, and any test results.

- Ensure that the installation complies with local electrical codes, standards, and regulations.

- Perform any necessary corrections or adjustments if any issues are identified during inspection and testing.

12. Maintenance:

- Periodically inspect the AAC conductor and support structures for signs of wear, damage, or corrosion.

- Perform routine maintenance to ensure the conductor's long-term reliability.

It's crucial to follow the specific guidelines provided by the conductor manufacturer and consult with local authorities or utility companies for any additional requirements or regulations that may apply to your installation project. Electrical installations should always be carried out by qualified professionals to ensure safety and reliability.

Dosense Cable factory produces bare aluminium conductors, in compliance to BS, ASTM, NFC,etc and customized specification. If you need to know about AAC Conductor, contact us freely.

- Previous:Power cable current carrying capacity

- Next:No

-

2023-10-02How to Install AAC Conductor

-

2023-08-30Power cable current carrying capacity

-

2022-03-17What are the cable accessories?

-

2022-07-01AWG (American Wire Gauge) to MM2 Conversion

-

2022-05-10OPGW Cable Line Design Several Key Issues[2]

info@dosensecable.com

info@dosensecable.com

Tel:

Tel:  Address: Zhengzhou, Henan,China

Address: Zhengzhou, Henan,China